content is empty!

LP

YUMO

YM0000541

| Availability: | |

|---|---|

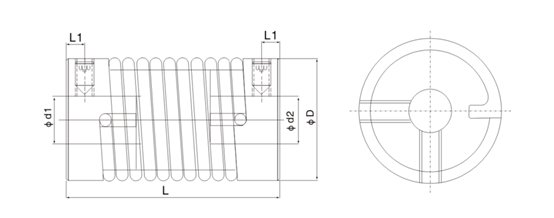

Use and characteristics

High torque, high torsional rigidity, high response.

Zero gap.

The presence of bias can also maintain constant velocity motion.

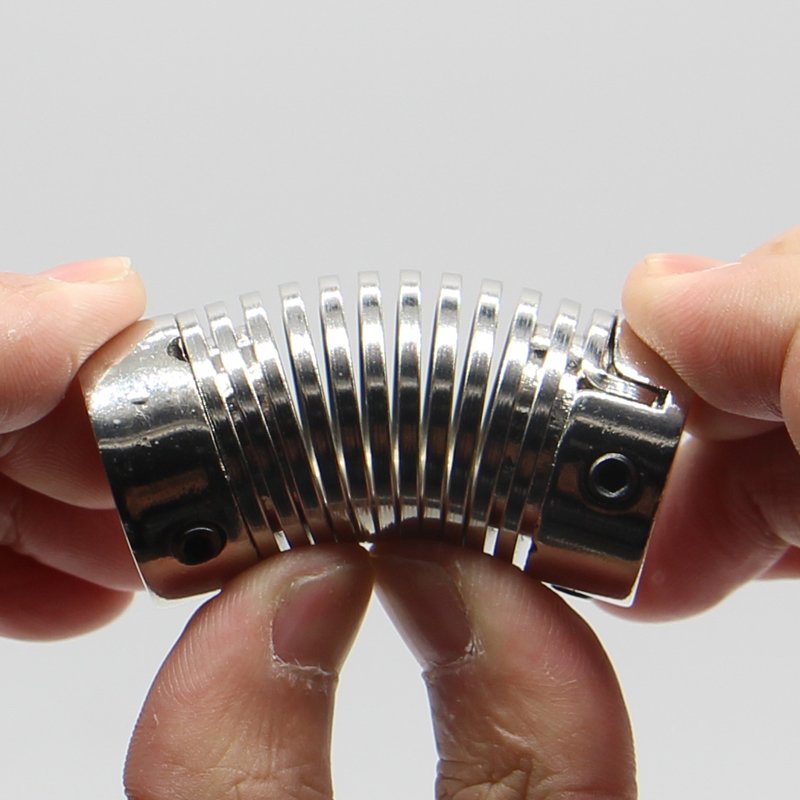

Softness, stainless steel spring can tolerate eccentricity, deflection angle and axis deviation wide error, adjustable.

Standardization of products with different diameters at both ends.

Applications

1. Widely used in various mechanical and hydraulic fields

2. Small dimension, low weight, high transmitted torque

3. Elastomers made of polyurethane with shore hardness between 80-98

4. Compensating the axial relative drift, buffer and vibration reduction

5. Material: cast iron, steel and aluminum alloy

| Model | D | L | d1 d2 Shaft Dia. | M |

| LP-16 24/XX/XX | 16 | 24 | 4-10 | 4-m4*6 |

| LP-16 35/XX/XX | 16 | 35 | 4-10 | 4-m4*6 |

| LP-26 38/XX/XX | 26 | 38 | 6-12 | 4-m5*8 |

| LP-26 55/XX/XX | 26 | 55 | 6-12 | 4-m5*8 |

| Model | Rated torque(N.m) | Max torque(N.m) | Max Speed(LPm) | Angular deviation(ºC) | Axial deviation(mm) |

| LP-16 24/XX/XX | 0.8 | 1.6 | 10000 | 1.5 | ±1.0 |

| LP-16 35/XX/XX | 0.8 | 1.6 | 10000 | 1.5 | ±1.0 |

| LP-26 38/XX/XX | 2 | 4 | 8000 | 2 | ±1.3 |

| LP-26 55/XX/XX | 2 | 4 | 8000 | 2 | ±1.3 |

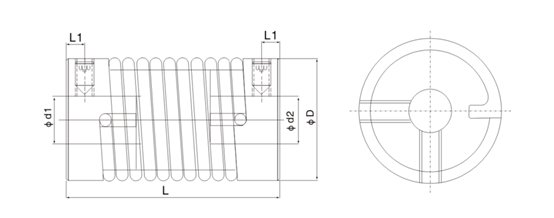

Use and characteristics

High torque, high torsional rigidity, high response.

Zero gap.

The presence of bias can also maintain constant velocity motion.

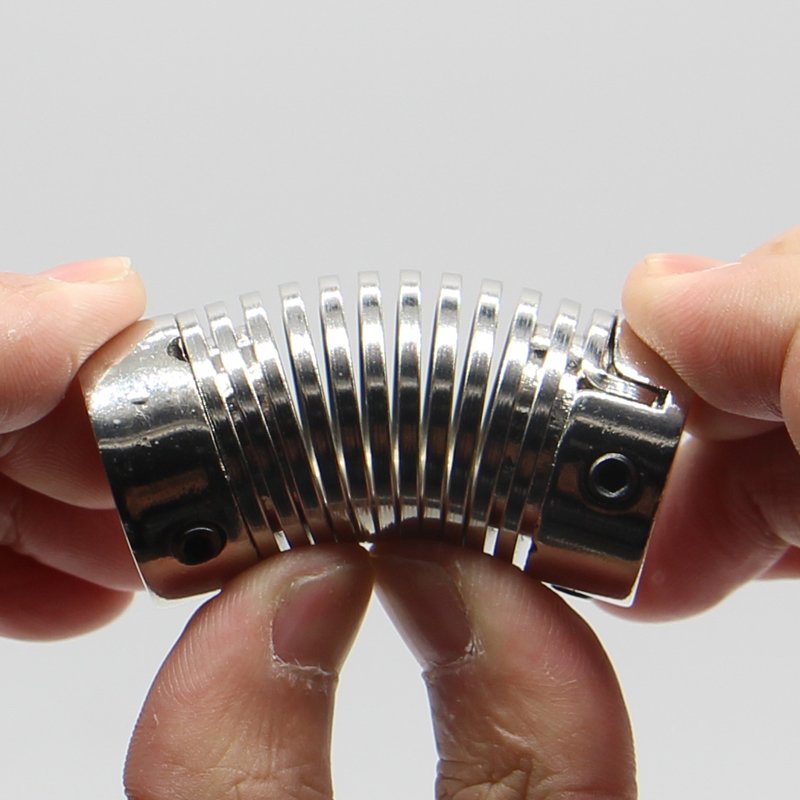

Softness, stainless steel spring can tolerate eccentricity, deflection angle and axis deviation wide error, adjustable.

Standardization of products with different diameters at both ends.

Applications

1. Widely used in various mechanical and hydraulic fields

2. Small dimension, low weight, high transmitted torque

3. Elastomers made of polyurethane with shore hardness between 80-98

4. Compensating the axial relative drift, buffer and vibration reduction

5. Material: cast iron, steel and aluminum alloy

| Model | D | L | d1 d2 Shaft Dia. | M |

| LP-16 24/XX/XX | 16 | 24 | 4-10 | 4-m4*6 |

| LP-16 35/XX/XX | 16 | 35 | 4-10 | 4-m4*6 |

| LP-26 38/XX/XX | 26 | 38 | 6-12 | 4-m5*8 |

| LP-26 55/XX/XX | 26 | 55 | 6-12 | 4-m5*8 |

| Model | Rated torque(N.m) | Max torque(N.m) | Max Speed(LPm) | Angular deviation(ºC) | Axial deviation(mm) |

| LP-16 24/XX/XX | 0.8 | 1.6 | 10000 | 1.5 | ±1.0 |

| LP-16 35/XX/XX | 0.8 | 1.6 | 10000 | 1.5 | ±1.0 |

| LP-26 38/XX/XX | 2 | 4 | 8000 | 2 | ±1.3 |

| LP-26 55/XX/XX | 2 | 4 | 8000 | 2 | ±1.3 |